Our mud pumps are engineered to handle abrasive fluids and slurry for mining, construction, and drilling applications, ensuring efficiency and durability.

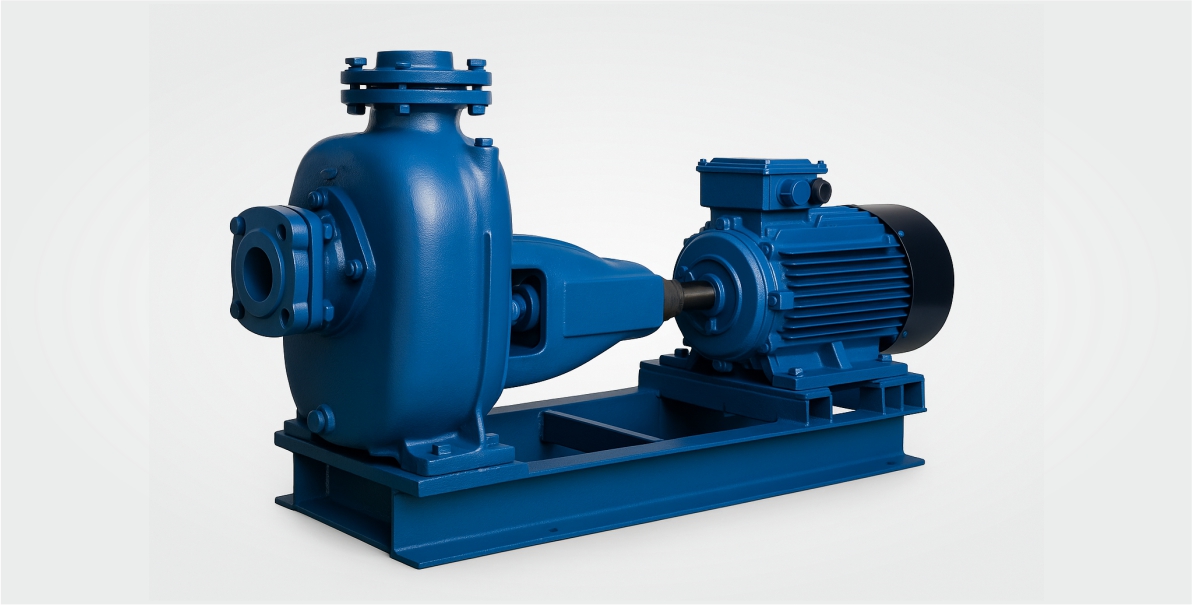

self priming pumps with foot-mounting & back pullout arrangement. The adoption of semi-open impeller permits its employment for pumping muddy liquids. Variey of MOC & constructional features can be adopted to suit the applications.

Constructional Optional for Centrifugal self priming mud pumps:

Shaft sealing arrangement such as mech. seal with suitable API plans & various type of gland packings with / without flushing arrangement suitable to applications available. Bearing arrangments suitable to applications available.

Jacketing for casing and stuffing box available.

Material of Construction for Centrifugal self priming mud pumps:

· GRADED GREY CAST IRON

· CARBON STEEL(WCB) / ALLOY STEEL

· CF8, CF8M,

· GUN METAL / BRONZE

Operating Range for Centrifugal self priming mud pumps:

|

Maximum flow capacity up to |

125 m3/hr |

|

Maximum total differential head upto |

45 MLC |

|

Maximum temperature |

150 °C |

|

Maximum operating pressure upto |

24 bars |

For operating requirments deferring from above please contact flowchem.

Application of Centrifugal self priming mud pumps:

Petrochem, Fertilizers, Pharmaceuticals industries, Bulk drugs Food Processing / Starch / Paper / Sugar plants, Edible / Castor Oil Refineries, Thermic Fluid Circulation, Fatty Acid distillation Plant etc.

Heavy-duty mud pumps for construction and mining

Efficient vertical circulation pumps designed for continuous fluid movement and industrial processes.

More Details

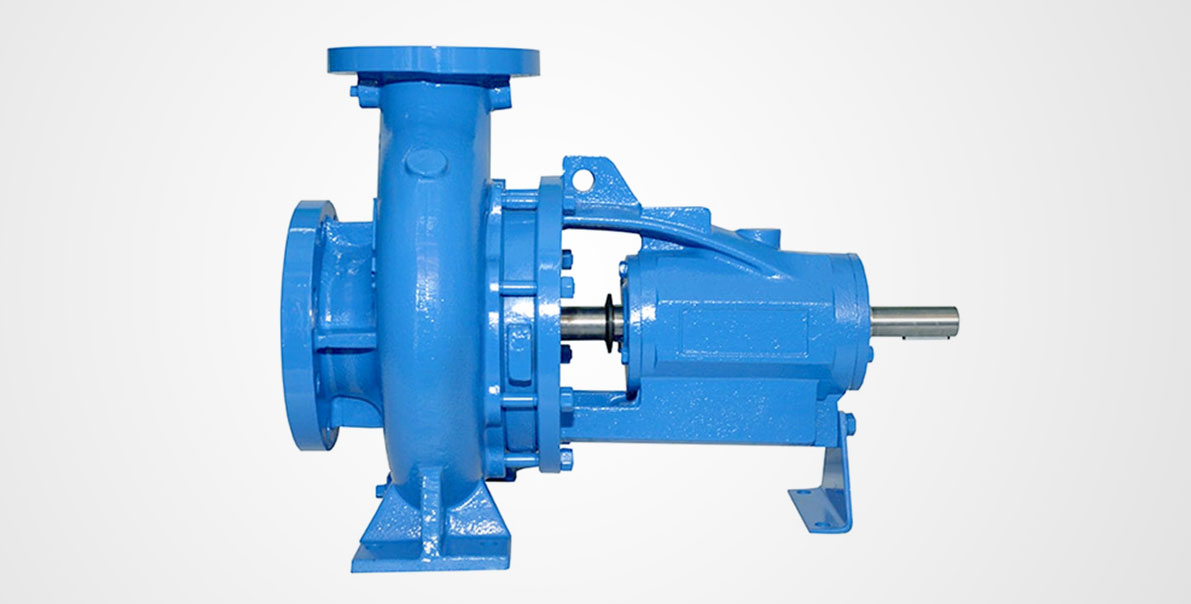

High-performance centrifugal process pumps designed for efficient fluid handling in industrial and commercial applications.

More Details

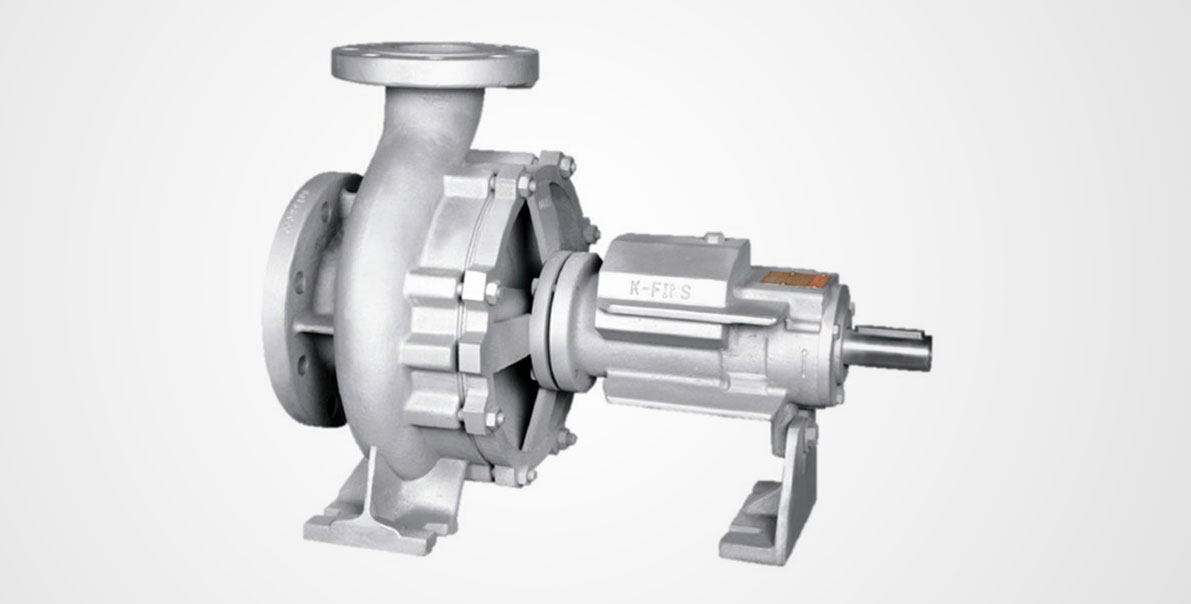

Reliable thermic fluid pumps designed for safe and efficient circulation of high-temperature heat transfer fluids in industrial systems.

More Details

Efficient centrifugal water pumps designed for reliable water transfer in industrial, commercial, and residential applications.

More Details

Durable and precise gear pumps designed for efficient fluid transfer in industrial and chemical applications.

More Details

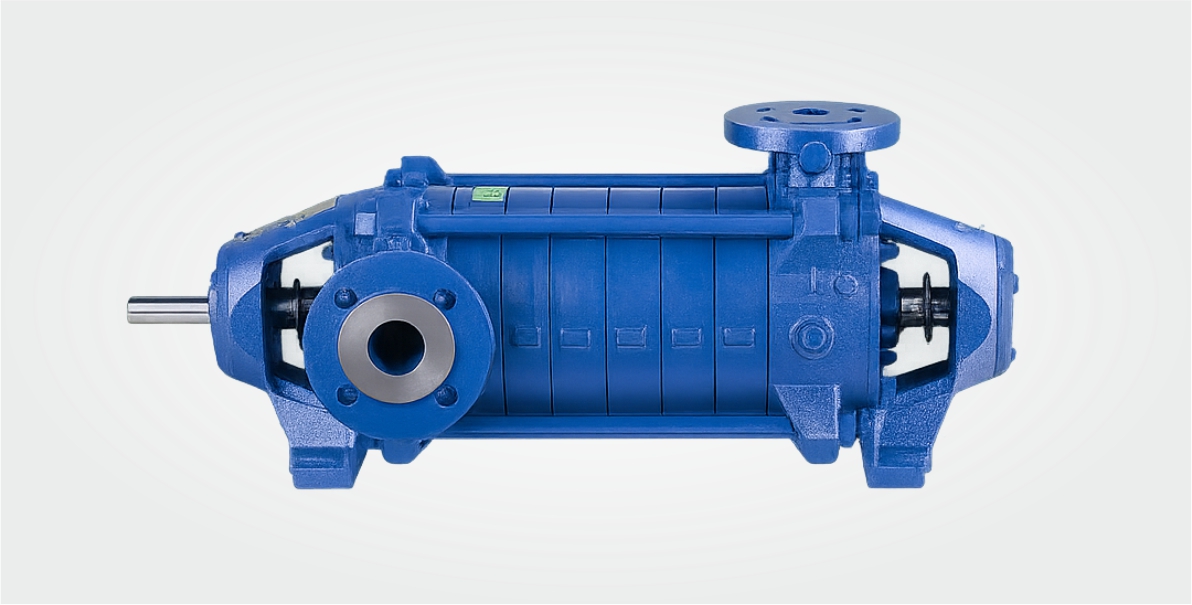

Reliable boiler feed pumps designed for efficient water supply to boilers, ensuring safe and continuous steam generation in industrial systems.

More Details