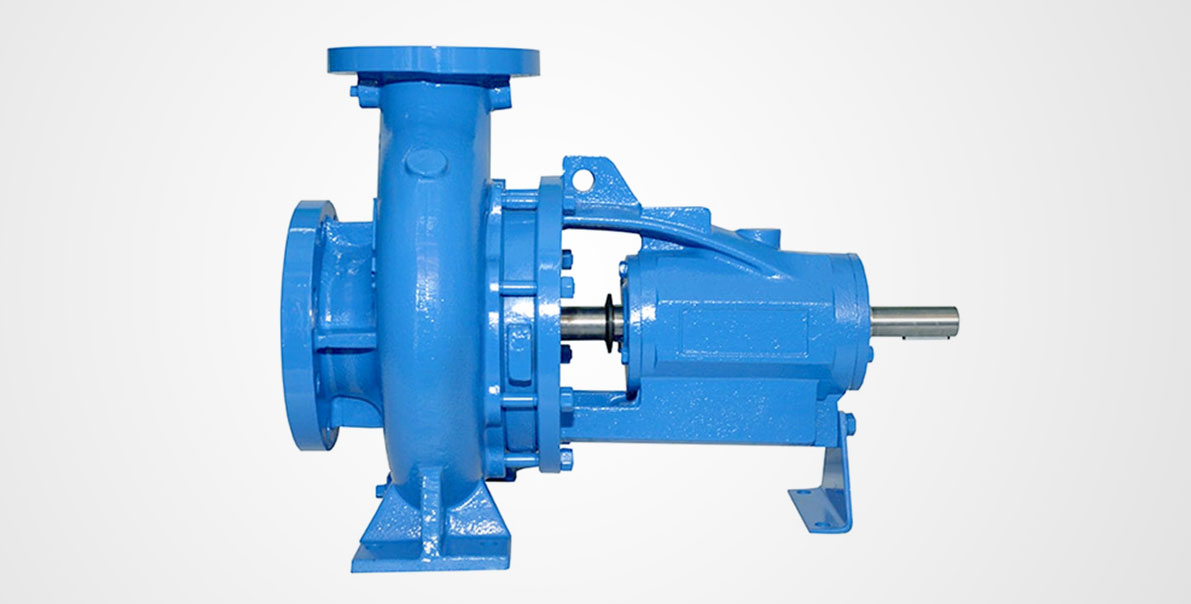

Our Centrifugal Process Pumps are engineered for reliable and efficient transfer of liquids across various industrial processes. Designed with precision, these pumps ensure smooth operation, high efficiency, and minimal maintenance. Suitable for chemical, pharmaceutical, food processing, and water treatment industries, they handle a wide range of fluids, including corrosive and abrasive liquids. Built with durable materials and advanced engineering, our centrifugal pumps provide long-lasting performance, reduced energy consumption, and superior operational reliability.

"Centrifugal Process Pumps" in Back Pull-out Construction , Horizontal, Foot Mounted, Single stage, End suction and Top Centerline Discharge, confirming to DIN 24256 / ISO 2858, standards and in general confirming to API 610 as well.

Process Pump Applications:

|

INDUSTRIES |

SERVICES |

|

CHEMICALS, DYES & INTERMEDIATES |

ORGANIC/INORGANIC CHEMICALS |

|

OIL EXTRACTION AND WASTE OIL REFINERIES |

HYDROCARBONS / VOLATILE LIQUIDS |

|

BULK DRUGS & PHARMACEUTICALS |

DYES & INTERMEDIATES |

|

EFFLUENT TREATMENT PLANTS |

WATER TREATMENT & DISTRIBUTION SYSTEM |

|

HEATING & AIR CONDITIONING PLANTS |

THERMIC FLUID / HOT OIL |

|

COOLING TOWERS |

CORROSIVE / ABBRASIVE LIQUIDS |

Construction Options for Centrifugal Process Pumps:

1. Centrifugal Process Pumps Offered with closed or Semi Open impeller.

2. Impellers are provided either with Back Vane or Back Wear Ring to minimize Axial Thrust and Gland Leakage.

3. Flange Rating PN 16 to PN 64 and drilled to DIN standard to meet ISO 2858 requirements.

4. Various Shaft Sealing Available are,

a. Gland Packing ( ASB. / NON ASB. depending on the service.)

b. Moulded Graphite Rings.( GRAFOIL PACKING )

c. Mechanical Seals (Single or Double Mechanical Seal Arrangements.).

6. Jacketing for heating/cooling offered for Casing, S/Box, Casing Pedestal and Bearing- Housing,

Materials of Construction for Centrifugal Process Pumps:

Operating Range for Centrifugal Process Pumps:

|

Capacity - Q - up to |

400 M³/hr. |

|

TDH - H - up to |

140 MLC |

|

Speed - n - |

960 / 1450 / 2900 rpm |

|

Temperature |

-10 ºC to +250 ºC |

|

Working Pressure |

40 Bars |

|

Pump sizes - DN - |

32 mm to 100 mm |

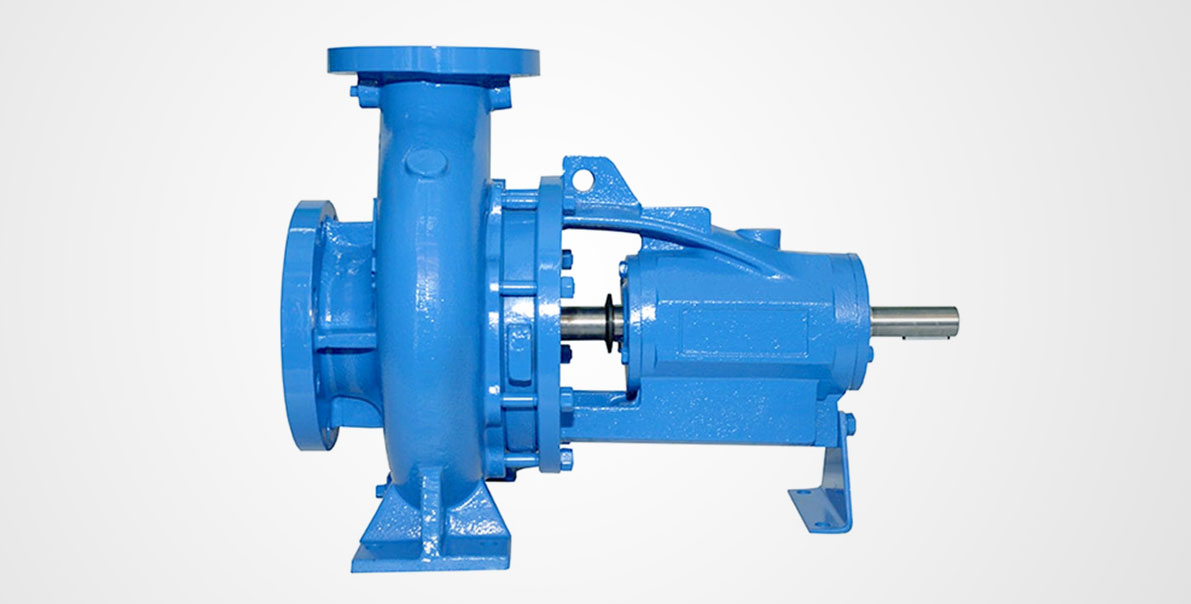

High-performance centrifugal process pumps designed for efficient fluid handling in industrial and commercial applications.

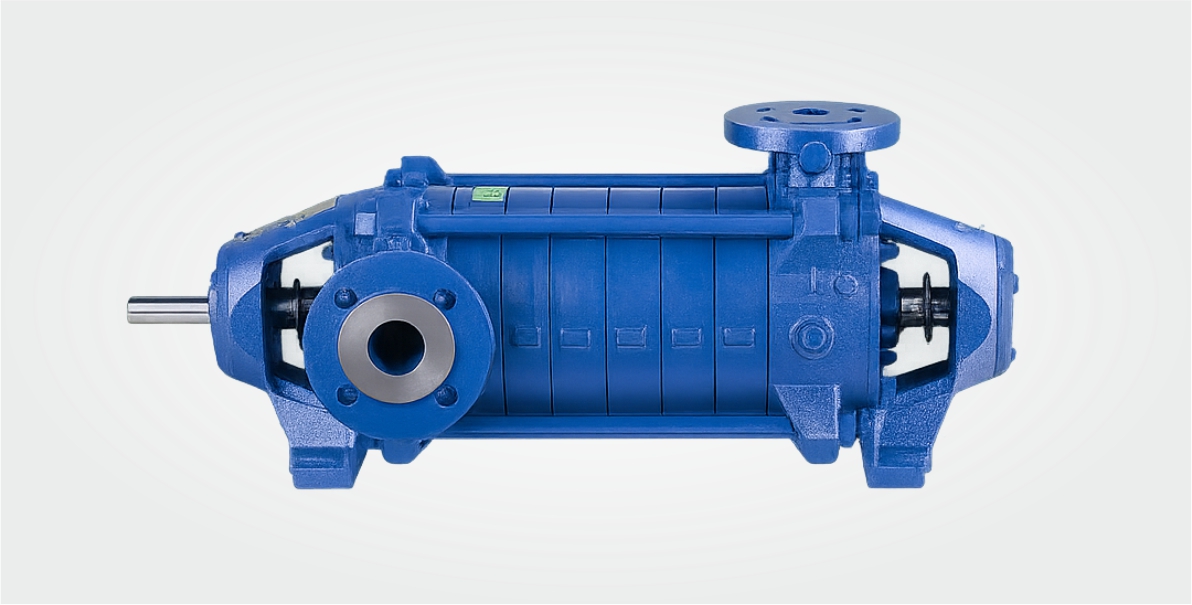

Reliable boiler feed pumps designed for efficient water supply to boilers, ensuring safe and continuous steam generation in industrial systems.

More Details

Durable and precise gear pumps designed for efficient fluid transfer in industrial and chemical applications.

More Details

High-performance centrifugal process pumps designed for efficient fluid handling in industrial and commercial applications.

More Details

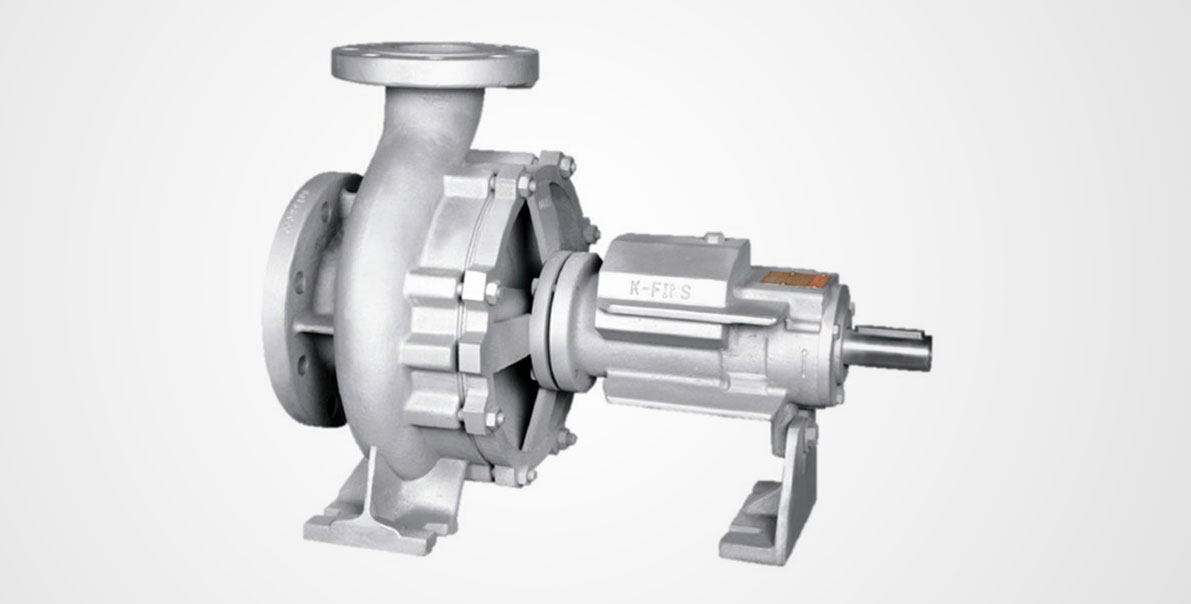

Reliable thermic fluid pumps designed for safe and efficient circulation of high-temperature heat transfer fluids in industrial systems.

More Details

Efficient centrifugal water pumps designed for reliable water transfer in industrial, commercial, and residential applications.

More Details

Efficient vertical circulation pumps designed for continuous fluid movement and industrial processes.

More Details